Comprehensive Overview of PVC Work Gloves for Industrial Applications

Which materials are used in the manufacturing of PVC gloves?

PVC Work Gloves in Croydon: PVC work gloves are meticulously crafted from polyvinyl chloride, a highly robust synthetic material renowned for its exceptional resistance to a variety of chemicals and oils. This extraordinary durability makes PVC gloves an ideal choice for numerous industrial applications across the UK. In busy manufacturing settings in cities like Manchester and London, workers rely on these gloves for their longevity and dependability. They are specifically engineered to withstand challenging operational conditions, ensuring maximum safety and comfort even during extended use. The unique composition of PVC also provides notable flexibility while maintaining structural integrity, an essential feature in environments where precision and dexterity are critical.

In settings where there is an elevated risk of exposure to hazardous materials, the combination of flexibility and strength becomes even more vital. Consequently, PVC gloves have become essential components in industries that enforce stringent safety protocols, including food-processing facilities located in Bristol and construction sites in Birmingham.

What advantages do PVC gloves provide in diverse work environments?

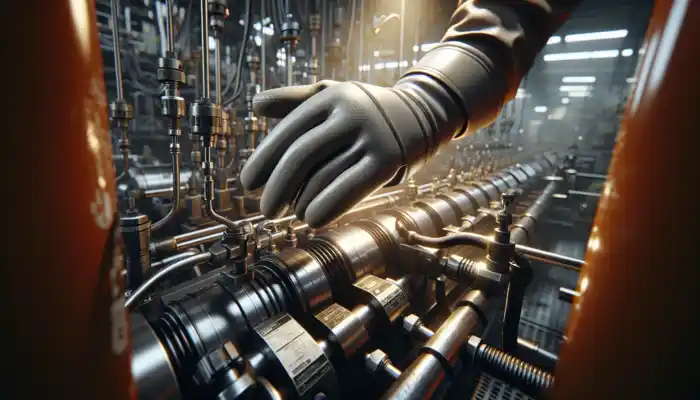

Utilising PVC gloves in the workplace yields a multitude of benefits, especially within the varied industrial landscape of the UK. These gloves are specifically designed to offer superior grip and flexibility, which are crucial for enhancing safety in environments such as warehouses, construction sites, and manufacturing plants. Another significant advantage is their cost-effectiveness; PVC gloves are generally more affordable than alternatives like latex or nitrile, making them an attractive option for businesses looking to manage costs without sacrificing quality. Additionally, their maintenance is uncomplicated, requiring only basic cleaning, which increases their practicality for daily use across various sectors.

Moreover, PVC gloves demonstrate resistance to a broad range of substances, including oils and specific chemicals, thereby minimising the potential for accidents caused by slippery surfaces. This characteristic is particularly important in workplaces where employees operate heavy machinery or handle substantial quantities of materials. In summary, the combination of affordability, safety features, and ease of maintenance solidifies PVC gloves as a wise choice for many workplaces throughout the UK.

How can I determine the correct size for PVC gloves?

Choosing the right size of PVC gloves is critical for ensuring optimal protection and comfort during their use. Ill-fitting gloves can lead to slippage, a common issue during heavy lifting or intricate tasks frequently performed in UK workplaces. To achieve the ideal fit, it is essential to consider several key measurements:

- Palm width

- Finger length

- Wrist circumference

- Overall glove length

Accurately measuring these dimensions and consulting the manufacturers’ size charts can significantly enhance the effectiveness of the gloves. A snug fit provides better control, reducing the likelihood of accidents, while gloves that are too tight may cause discomfort and restrict movement. Therefore, taking the time to select the right size is essential for maintaining safety and productivity in your work environment.

Professional Insights on Acquiring PVC Work Gloves in Croydon

What essential features should I look for according to experts?

Industry professionals highlight several vital features to consider when selecting PVC work gloves. One of the most crucial elements is the presence of reinforced cuffs, which provide additional protection against debris and chemicals—especially in UK environments where exposure risks are prevalent. When selecting high-quality gloves, consider aspects such as reinforced seams, enhanced grip patterns, and chemical resistance. These features not only improve durability but also ensure that the gloves are suitable for specific tasks, whether in construction, cleaning, or food processing.

Additionally, specialists advise paying close attention to the thickness of the material. Thicker gloves might provide better protection but could compromise dexterity. Evaluating the specific task at hand will guide you in selecting the appropriate glove thickness. Consulting with industry professionals or suppliers can be invaluable when determining the right features tailored to your specific workplace requirements.

What errors should I avoid when placing an order for gloves?

When ordering PVC gloves, it is critical to avoid common pitfalls that could lead to dissatisfaction or safety hazards. A significant concern is neglecting glove thickness, which can greatly affect durability—especially in the often rainy conditions of the UK, where moisture can accelerate wear and tear. Another frequent mistake is failing to consider the specific requirements of your work environment, including the types of chemicals or substances that employees might handle.

Furthermore, neglecting to verify that the gloves comply with UK safety standards can lead to costly mistakes. Always ensure that the gloves are certified for the specific industry standards relevant to your workplace. By being aware of these issues and conducting thorough research, you can guarantee that you order gloves that adequately meet your needs, thereby enhancing workplace safety and efficiency.

What is the long-term value of investing in high-quality gloves?

Investing in high-quality PVC work gloves provides significant long-term value that transcends initial costs. Quality gloves considerably enhance workplace efficiency, with numerous experts observing a decrease in hand injuries and the associated downtime once suitable gloves are employed. For instance, a case study from a UK construction firm demonstrated that transitioning to premium PVC gloves resulted in a 25% reduction in injuries and generated substantial long-term cost savings from fewer claims and replacements.

This financial advantage stems from lower healthcare expenses and increased productivity, as workers feel more secure and confident while executing their responsibilities. Quality gloves can withstand the demands of daily use, delivering a longer lifespan than cheaper alternatives. As a result, the initial investment in superior gloves can yield significant long-term savings, underscoring their importance in any industrial setting.

What do experts recommend when sourcing local suppliers in Croydon?

When purchasing PVC work gloves in Croydon, it is essential to select suppliers known for their commitment to quality and adherence to UK safety standards. Local industry professionals suggest sourcing from reputable suppliers who prioritise customer service and reliability. Evaluating potential suppliers involves more than just examining their product offerings; factors such as delivery times, stock availability, and the responsiveness of customer support should also be taken into account.

Additionally, it is wise to review online feedback and seek recommendations from colleagues within the industry. Engaging with local suppliers not only supports the community but also ensures that you receive products tailored to your specific needs. Furthermore, local suppliers often possess a better understanding of regional regulations and requirements, facilitating a smoother ordering process and enhancing customer satisfaction.

What steps should I follow to order PVC Work Gloves effectively?

What are the key steps in the ordering process for PVC gloves?

The process of ordering PVC work gloves typically begins with assessing your specific needs based on the tasks you plan to undertake. Gaining a clear understanding of the environment in which the gloves will be utilised is crucial. After this initial evaluation, you can proceed to select suitable options from various UK suppliers. Many suppliers offer purchasing options both online and in-store, allowing you to choose the method that best accommodates your needs.

It is advisable to review product specifications and customer feedback to make informed decisions. When ordering online, ensure you check delivery times and policies, particularly if you require gloves urgently for an impending project. Conversely, in-store purchases allow for hands-on evaluation, which can be beneficial for assessing fit and comfort. Ultimately, following these steps will streamline your purchasing experience and enhance satisfaction with your final selection.

Why should I favour local suppliers in the UK for PVC gloves?

Choosing local suppliers for your PVC work gloves offers numerous advantages that can greatly benefit businesses operating within the UK. Firstly, sourcing locally significantly reduces delivery times, ensuring that you receive your products promptly and can maintain efficient operations. Additionally, supporting British businesses bolsters local economies and fosters sustainable practices.

- Faster shipping times

- Access to a broader selection of local products

- Improved understanding of regional regulations

- Enhanced customer service and support

Furthermore, many local suppliers offer customisation options, allowing you to order gloves that meet your industry-specific requirements. This flexibility is particularly valuable for businesses with unique safety needs or branding guidelines. Overall, opting for local suppliers enhances operational efficiency while strengthening community ties.

What factors can influence delivery times for PVC gloves?

Delivery times for PVC work gloves can be affected by various elements within the UK logistics framework. One of the primary factors is stock availability; if the gloves are not readily available in the supplier’s inventory, it may lead to extended wait times. Additionally, the volume of the order can impact processing time; larger orders may require more time for processing, depending on the supplier’s capabilities and logistics.

Planning ahead is essential to ensure that your needs are met without unnecessary delays. If you anticipate needing gloves for a specific project, placing your order well in advance can help mitigate the risk of stock shortages or shipping delays. By considering these factors, you can more effectively integrate the ordering process into your workplace routines.

Research-Driven Advantages of Ordering PVC Work Gloves in Croydon

How do PVC gloves enhance workplace safety?

PVC work gloves significantly improve safety in various industrial environments by providing robust chemical resistance, thus reducing the risk of injuries in UK factories. This feature is particularly crucial in settings where employees may be exposed to hazardous substances. To effectively incorporate these gloves into daily operations, it is advisable to conduct training sessions that emphasise their benefits and proper usage.

Moreover, promoting routine glove inspections for wear and tear can help ensure ongoing safety and performance. Research indicates that workplaces implementing safety training and proper glove practices experience fewer accidents, thereby fostering a safer work environment.

What environmental benefits are associated with using PVC gloves?

One of the often-overlooked advantages of PVC work gloves is their environmental impact. Sustainable production methods employed in the UK help to minimise waste, making these gloves a more responsible choice for environmentally conscious businesses. Several manufacturers have begun embracing eco-friendly practices, such as recycling materials and reducing harmful emissions during production.

Choosing PVC gloves produced through these methods not only supports local businesses but also aligns with broader environmental objectives. Companies committed to sustainability can highlight these practices in their corporate social responsibility initiatives, enhancing their reputation while equipping employees with effective protective gear.

How do PVC gloves influence productivity in the workplace?

The effect of PVC gloves on productivity is noteworthy, particularly due to their enhanced dexterity and grip. Various studies conducted in UK workplaces have revealed that employees equipped with quality gloves experience a significant increase in efficiency. For instance, in a manufacturing setting in Sheffield, workers reported completing tasks 20% faster when utilising PVC gloves compared to standard alternatives.

This performance boost is attributed to the gloves’ secure fit and reliable grip, which minimise the likelihood of accidents and errors. Consequently, investing in PVC work gloves can lead to substantial productivity improvements, making them an invaluable asset for any organisation striving to optimise workflow while adhering to safety standards.

What is the expected durability and longevity of PVC work gloves in industrial settings?

Research conducted by UK institutions has demonstrated that PVC work gloves exhibit exceptional durability and wear resistance, particularly in challenging industrial environments. For example, trials conducted in manufacturing facilities based in Croydon revealed that these gloves maintained their structural integrity even after extensive use. Factors contributing to their longevity include material composition, design features, and adherence to proper usage protocols.

To maximise the lifespan of PVC gloves, it is crucial to implement best practices for storage and usage. Storing gloves in a cool, dry environment and avoiding exposure to extreme temperatures can prevent degradation. Regular cleaning and inspections can also identify potential issues before they result in significant wear and tear, ensuring sustained performance and reliability over time.

What varieties of PVC gloves are available in the market?

How can you differentiate between coated and uncoated PVC glove varieties?

When selecting PVC work gloves, it is important to distinguish between coated and uncoated varieties. Coated gloves generally offer superior waterproofing, making them ideal for outdoor tasks or jobs involving exposure to moisture, thus being a preferred choice for UK tradespeople working in rainy conditions. The coating enhances the glove’s water and chemical resistance, providing an extra layer of protection.

Conversely, uncoated gloves may provide better breathability and dexterity, making them suitable for tasks such as assembly, where precision is crucial. Understanding these differences can significantly assist in making the right selection for specific tasks, ensuring safety and efficiency within the workplace.

Are there specialised PVC glove options designed for specific industries?

Specific PVC glove varieties are tailored to meet the unique requirements of various industries in the UK. For instance, gloves intended for construction may feature additional padding or reinforced fingertips to endure heavy use and provide enhanced protection against cuts and abrasions. In contrast, gloves designed for food handling emphasise hygiene and grip to ensure safety during food preparation and service.

By understanding the distinct needs of your industry, you can choose gloves that not only comply with safety standards but also enhance performance. Numerous suppliers offer industry-specific options, allowing you to effectively match gloves to your sector’s requirements.

What factors contribute to the durability of certain PVC gloves?

The durability of PVC work gloves is often attributed to various design features and material innovations. For example, gloves with reinforced palms can significantly extend their service life, particularly in high-wear environments such as construction sites or warehouses. The adoption of advanced manufacturing techniques, including double stitching and high-quality PVC formulations, also plays a critical role in enhancing durability.

Choosing gloves from reputable manufacturers known for their quality can ensure that you are investing in durable products. Assessing material thickness and design features during the selection process can facilitate informed decisions, ultimately leading to longer-lasting protective gear.

Essential Maintenance Practices for Your PVC Work Gloves

Why is establishing a regular cleaning routine essential?

Regular cleaning of PVC work gloves is vital for maintaining hygiene and preventing contamination across various work environments throughout the UK. Proper maintenance practices not only extend the gloves’ lifespan but also ensure they continue to provide adequate protection against hazardous substances. Failing to clean gloves after each use can result in the buildup of dirt, chemicals, and other contaminants, compromising their integrity.

Establishing a routine cleaning schedule and educating employees on proper glove care can significantly enhance workplace safety and efficiency. Simple cleaning techniques can greatly reduce the risk of cross-contamination, particularly in sensitive sectors such as food processing or healthcare. Thus, incorporating regular cleaning into your glove maintenance protocol is both prudent and yields long-term benefits.

What is the proper way to store PVC gloves?

Correct storage of PVC work gloves is crucial to prevent degradation and ensure their longevity, especially considering the UK’s variable weather conditions. Keeping gloves dry is essential, as moisture can lead to mould growth and material degradation. To optimise storage conditions, consider implementing the following suggestions:

- Store gloves in a cool, dry location

- Utilise ventilated storage bags

- Avoid exposure to sunlight or heat sources

- Keep gloves away from sharp objects

By following these practices, you can significantly prolong the lifespan of your gloves, ensuring they remain effective and safe for use. Proper storage is a critical aspect of glove maintenance that should not be overlooked.

What indicators suggest that gloves need to be replaced?

Recognising the signs that PVC work gloves require replacement is vital for upholding safety standards in the workplace. Areas of wear, such as thinning material or visible tears, indicate reduced protection and should not be disregarded. Regularly inspecting gloves for these signs can help prevent accidents and ensure that workers are adequately protected during their tasks.

Furthermore, any noticeable changes in grip performance or comfort may also necessitate a review of the gloves’ condition. Proactively monitoring glove wear is essential for maintaining safety and efficiency throughout your operations, emphasising the importance of routine inspections as part of your workplace safety protocols.

What are the recommended drying techniques after using gloves?

After cleaning PVC work gloves, ensuring proper drying is crucial to prevent mould growth, particularly in the UK’s humid conditions. The best practice for drying is to air-dry the gloves in a well-ventilated area, allowing moisture to evaporate effectively. Avoid placing gloves in direct sunlight or near heat sources, as excessive heat can damage the materials and compromise their integrity.

Before storing gloves, ensure they are completely dry to maintain their quality and ensure ongoing safety. Taking the time to implement appropriate drying techniques not only extends the lifespan of your gloves but also mitigates the risk of contamination and enhances workplace safety.

Where can you find Quality Gloves in the UK?

Which online platforms offer reliable PVC glove options?

Several reputable UK online retailers provide an extensive selection of PVC work gloves with fast delivery options. Websites such as Screwfix, Amazon UK, and SafetyGloves.co.uk present vast inventories tailored to a variety of industrial needs. These platforms frequently showcase user reviews that can aid in guiding purchasing decisions based on others’ experiences.

In addition to this, many online retailers offer detailed product descriptions and specifications, allowing you to match gloves to your specific requirements. With the convenience of online shopping, ordering gloves has become more straightforward than ever, providing access to quality products at competitive prices.

How do prices for PVC gloves compare among different suppliers?

Price comparisons for PVC work gloves can vary significantly among suppliers, influenced by factors such as features, brand reputation, and bulk purchasing discounts. Generally, higher-quality gloves come with a premium price; however, they also provide enhanced durability and protection, making them a worthwhile investment for many UK businesses. Some suppliers may offer bulk-buying options, which can result in more cost-effective purchasing.

Additionally, seasonal promotions and discounts can further influence pricing, highlighting the importance of staying informed about current offers from various retailers. By comparing prices and considering the features that matter most to your workplace, you can ensure that you receive excellent value for your investment.

What advantages do in-store purchases offer for PVC gloves?

Purchasing PVC work gloves in-store can be beneficial, especially for those who prefer a hands-on assessment before making a purchase. Physical stores located in UK high streets or industrial areas allow customers to evaluate glove fit, comfort, and quality, which can help ensure the right choice for specific tasks. This tactile experience aids in preventing sizing issues.

While online shopping provides convenience, in-store purchases offer the opportunity to interact directly with knowledgeable staff who can provide tailored recommendations based on your industry needs. Striking a balance between the advantages of both options can lead to more informed purchasing decisions for your workplace safety equipment.

Essential Recommendations for the Safe Usage of PVC Work Gloves

What safety precautions should users implement when using gloves?

Implementing safety precautions while using PVC work gloves is essential for protecting workers in UK work environments. Always conduct thorough inspections of gloves before use to identify any signs of damage or wear. This proactive measure can help prevent accidents and ensure the gloves provide the required protection against hazardous materials.

Moreover, educating employees on proper glove usage and limitations can significantly enhance workplace safety. For instance, while PVC gloves offer excellent chemical resistance, they may not be suitable for all chemicals—communicating this information helps mitigate risks associated with improper use. Actively promoting safety protocols ensures a safer environment for all employees.

How can gloves be paired effectively with other protective gear?

Combining PVC gloves with additional protective gear significantly enhances overall safety across various British industries. For instance, when dealing with hazardous materials, pairing gloves with appropriate eye protection, such as safety goggles or face shields, creates a comprehensive safety protocol. Ensuring that workers are equipped with the right combination of protective equipment can drastically reduce the risk of injury.

Additionally, including high-visibility clothing or helmets can further bolster safety, particularly in construction or roadworks. Taking a holistic approach to personal protective equipment (PPE) ensures that all facets of worker safety are considered, fostering a culture of safety within the workplace.

What common errors should be avoided to ensure safety while using gloves?

Several common errors can undermine safety when using PVC work gloves. One significant mistake is disregarding the fit; poorly fitting gloves can lead to accidents due to slippage or loss of dexterity. Other frequent issues include improper disposal of worn gloves and neglecting to follow the manufacturer’s guidelines for usage and maintenance.

- Neglecting to inspect gloves for damage before use

- Using the incorrect type of glove for specific tasks

- Failing to clean gloves after use

- Inadequate training on proper glove usage

Being vigilant about these errors and providing ongoing training and reminders to employees can greatly enhance safety protocols, promoting a safer work environment.

What environmental considerations should be made during the disposal of gloves?

When disposing of PVC work gloves, it is essential to consider their environmental impact within the UK. Opting for recycling options wherever possible helps reduce landfill waste and encourages sustainable practices. Many manufacturers are implementing take-back programmes or recycling initiatives, making it easier for businesses to dispose of gloves responsibly.

Moreover, complying with local waste management guidelines is crucial to minimising pollution and ensuring adherence to environmental regulations. By integrating environmentally responsible disposal practices into your workplace, you contribute to broader sustainability efforts while maintaining safe usage standards for all employees.

Frequently Asked Questions (FAQs) on PVC Work Gloves

What materials are used in the production of PVC work gloves?

PVC work gloves are manufactured from polyvinyl chloride, a robust synthetic material recognised for its resistance to chemicals and oils, making them ideal for various industrial applications.

How do I select the correct size of PVC gloves?

To choose the right size, measure your palm width and finger length, and refer to the manufacturer’s size chart to ensure a proper fit and minimise slippage.

Why are reinforced cuffs significant in enhancing glove safety?

Reinforced cuffs provide additional protection against debris and chemicals, enhancing safety in environments where exposure risks are common.

What maintenance practices are essential for PVC work gloves?

PVC gloves require regular cleaning to prevent contamination, proper storage in cool, dry locations, and routine inspections for wear and tear to ensure longevity.

Where can I order PVC work gloves in Croydon?

Local suppliers in Croydon are accessible both online and in physical stores, offering a variety of PVC work gloves that comply with UK safety standards.

Is it possible to receive bulk discounts on PVC gloves?

Yes, many suppliers offer bulk purchasing options that can result in significant discounts, making it more cost-effective for businesses to order gloves in larger quantities.

Are there PVC gloves specifically designed for food handling?

Indeed, there are PVC gloves specifically designed for food handling, focusing on hygiene, grip, and compliance with food safety regulations.

How can I ensure the durability of my PVC gloves?

To maximise glove longevity, store them correctly in a cool, dry location, clean them after each use, and inspect them regularly for signs of wear.

What should I do if my gloves tear during use?

If your gloves tear while being used, cease operations immediately, dispose of the damaged gloves, and replace them with a new pair to ensure ongoing protection.

Can PVC gloves be recycled responsibly?

Many PVC gloves can indeed be recycled, but it is important to consult local regulations and manufacturer guidelines to determine the most appropriate disposal methods.

Connect with us on Facebook!

The Article: Order PVC Work Gloves in Croydon: Key Benefits first published on https://www.gloveclub.co.uk

The Article PVC Work Gloves in Croydon: Discover Their Key Benefits Was Found On https://limitsofstrategy.com