Maximise the Aesthetic Appeal of Your Limestone Surfaces with Polishing Powder

Limestone polishing powder is a vital product for revitalising and enhancing limestone surfaces, injecting them with renewed elegance and vitality. This remarkable product comprises finely ground limestone particles, often artfully blended with specialised minerals and abrasives to optimise its polishing capabilities. The distinct formulation of limestone polishing powder not only rectifies surface imperfections but also accentuates the inherent beauty of limestone, ensuring your surfaces radiate as if they were just installed.

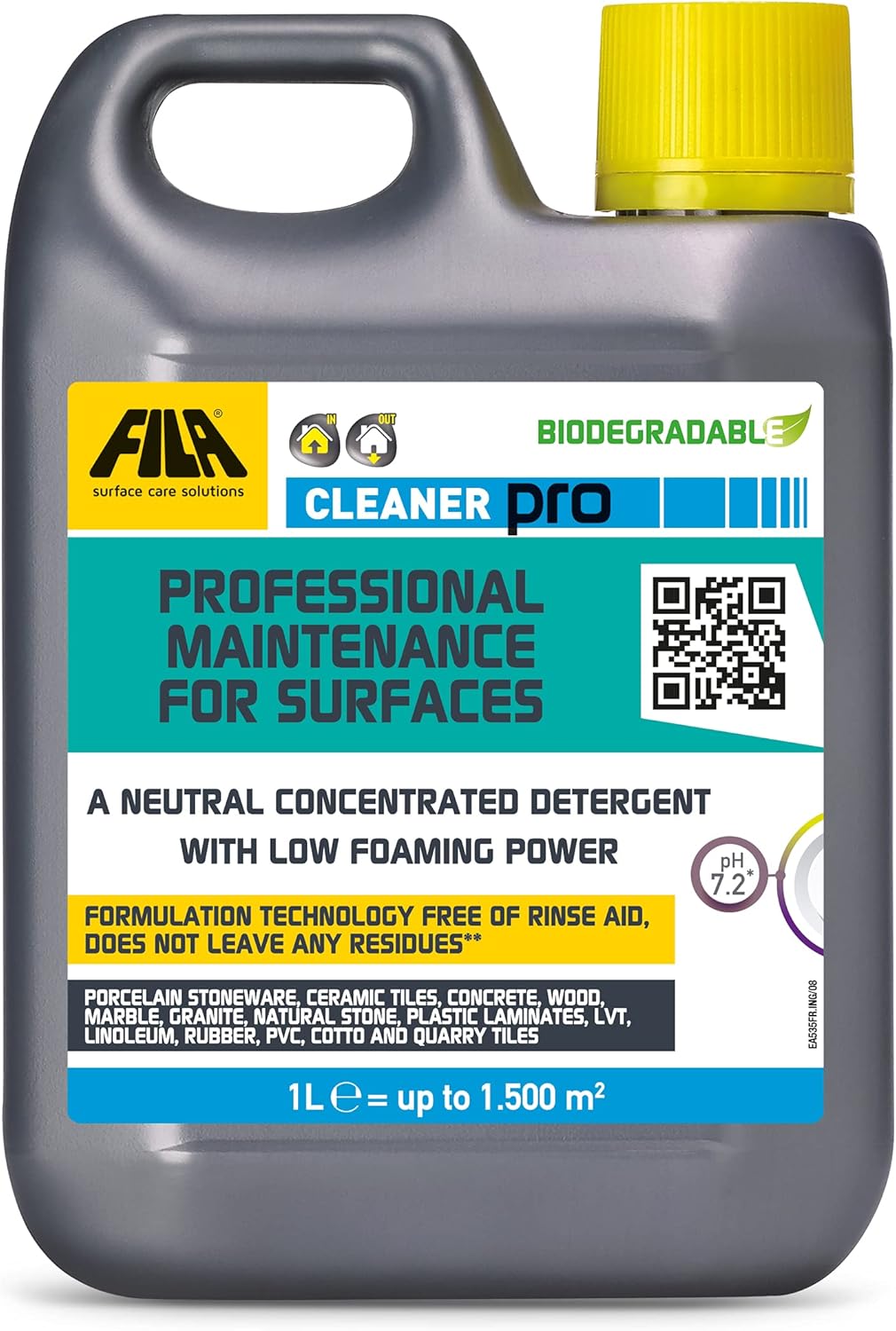

Expert Insight: Discover Our Recommended Products for Effortless Daily Maintenance

Understanding the role of polishing powder underscores its critical function in the maintenance of limestone surfaces. This powder employs a gentle abrasive technique specifically designed to carefully remove scratches and imperfections that accumulate over time. Upon application, it effectively polishes the surface, restoring a brilliant sheen that is visually appealing. This transformation is particularly essential for older or frequently used limestone surfaces, which may have lost their aesthetic charm due to ongoing wear and tear.

The benefits of utilising limestone polishing powder extend beyond mere visual enhancements. Revitalising your surfaces can significantly enhance their durability and longevity. When limestone is polished correctly, it becomes increasingly resistant to stains and damage, making it an exceptional choice for high-traffic areas in both residential and commercial settings. The ultimate outcome is a surface that is not only stunningly attractive but also robust, capable of enduring the demands of daily use, establishing this powder as an essential tool for homeowners and contractors alike.

Delve into the Complex Composition of Limestone Polishing Powder

The essence of limestone polishing powder lies in its meticulously crafted composition. Primarily, it is composed of ultra-fine limestone particles that are skillfully ground to achieve a specific texture. This fine consistency enables the powder to be evenly spread across surfaces, ensuring a comprehensive application that maximises effectiveness. What distinguishes this powder is its combination with additional minerals and abrasives that enhance its polishing capacities. These ingredients may encompass various fine abrasives that smooth surfaces without causing harm, along with components that contribute to achieving a brilliant sheen.

When selecting a limestone polishing powder, it is crucial to take into account the specific type of limestone being used, as different stones may respond variably to various formulations. Certain powders are tailored specifically for softer limestones, while others may be more appropriate for harder varieties. This specificity not only guarantees effective results but also protects the integrity of the surface being treated. Therefore, understanding the formulation of your chosen powder is essential for achieving the desired outcomes while maintaining the quality of the stone.

Opting for a high-quality limestone polishing powder can greatly impact the polishing experience. Subpar products may fail to meet expectations or, worse, could potentially damage the limestone surface. Consequently, investing in a reputable brand that clearly discloses its components can make a significant difference. Always remember that the correct formulation strikes the perfect balance between effectiveness and protecting your limestone’s natural beauty.

Understand the Mechanics of How Limestone Polishing Powder Functions

To fully grasp the functionality of limestone polishing powder, one must examine its operational mechanics. The powder acts as an abrasive material that gently polishes the surface of limestone. Upon application, it interacts with the stone to eliminate dirt, stains, and superficial scratches. This process not only enhances the surface’s overall appearance but also revitalises its natural glow. The key to effective polishing resides in the abrasiveness of the powder; a coarser formulation can inadvertently create scratches, while a finer one may not attain the desired sheen.

The application method plays a pivotal role in the efficacy of the powder. When applying limestone polishing powder, it should be done with precision. Typically, this involves sprinkling the powder over the surface and employing a polishing machine or hand pad to buff it in. The pressure applied, along with the duration of polishing, can significantly influence the final result. A careful approach will yield a smoother finish, enhancing the surface’s lustre to a level reminiscent of a brand-new installation.

Furthermore, the polishing process extends beyond mere aesthetics; it also strengthens the physical characteristics of limestone. As the surface is polished, it becomes less porous, thereby diminishing the likelihood of water and stains penetrating the stone. This enhanced durability is particularly advantageous in areas prone to spills, such as kitchens and bathrooms. Essentially, understanding how limestone polishing powder operates empowers you to harness its potential, ensuring your limestone surfaces remain not only visually stunning but also structurally sound for years to come.

Uncover the Extensive Benefits of Limestone Polishing Powder

The advantages of using limestone polishing powder are both extensive and varied. Primarily, it provides an unparalleled enhancement in aesthetics. Polished limestone surfaces are visually captivating, displaying a glossy finish that beautifully reflects light. This transformation can significantly improve the atmosphere of a room, making it feel more vibrant and welcoming. Whether your goal is to refresh a worn kitchen countertop or revive the allure of a historic limestone floor, polishing powder offers the perfect solution.

Additionally, employing limestone polishing powder prolongs the lifespan of your surfaces. As mentioned earlier, polished limestone becomes increasingly resistant to staining and damage, especially in high-traffic areas. Investing in polishing not only amplifies visual appeal but also translates to long-term savings by reducing the necessity for repairs or replacements. In commercial environments, maintaining a polished appearance can elevate the overall brand image, fostering a welcoming atmosphere for clients and customers alike.

Moreover, the application of polishing powder can be a straightforward process, making it an attractive option for both DIY enthusiasts and professional contractors. With the right preparation and technique, anyone can achieve remarkable results. This ease of use, combined with the significant benefits, makes a compelling case for incorporating limestone polishing powder into your maintenance routine. Ultimately, the impact of investing in this powder is profound; it’s about preserving the beauty and integrity of your limestone surfaces while ensuring they remain functional and appealing for years to come.

Investigate the Diverse Applications of Limestone Polishing Powder

When exploring the uses of limestone polishing powder, its versatility becomes abundantly evident. It is suitable for a wide variety of surfaces, including limestone floors, countertops, and various decorative items. The adaptability of this polishing powder allows it to cater to diverse needs, whether you aim to restore a magnificent entryway or elevate the appearance of a simple tabletop.

In residential settings, limestone polishing powder proves especially beneficial in kitchens and bathrooms. These spaces frequently encounter challenges with stains, scratches, and general wear due to heavy usage. Applying polishing powder can restore the original texture and colour of limestone, enhancing the aesthetic appeal and hygiene of these areas. The user-friendly nature of the product allows homeowners to tackle the task themselves, transforming it into a satisfying DIY project that yields significant benefits.

In commercial establishments, limestone polishing powder is a staple in hotels, restaurants, and other public venues where visual appeal is paramount. In these contexts, maintaining a pristine appearance is crucial for attracting and retaining customers. Polishing limestone surfaces not only boosts their attractiveness but also contributes to a clean and inviting environment. Using polishing powder in these scenarios signifies an investment in both aesthetics and durability, ensuring that surfaces withstand the rigours of high foot traffic.

However, it is essential to recognise the limitations of limestone polishing powder. While it is highly effective on limestone surfaces, applying it to other materials can lead to damage and undesirable outcomes. Therefore, it’s crucial to ensure you are using it on the correct surfaces. Additionally, due to the powder’s nature, wearing protective gear during application is vital to prevent inhalation and skin irritation. This precaution is essential for ensuring a safe and effective polishing experience.

Identify the Ideal Surfaces for Polishing with Limestone Powder

Recognising where to apply limestone polishing powder is vital for achieving optimal results. Primarily, it is specifically formulated for use on limestone surfaces, including floors, countertops, and various decorative features. The powder excels in restoring the natural beauty of these surfaces, enhancing their shine and ensuring a well-maintained look. Limestone, being a porous stone, is susceptible to scratches and stains, making it an ideal candidate for polishing to enhance its durability while preserving its aesthetic appeal.

Limestone floors endure considerable foot traffic, resulting in wear and tear that detracts from their visual allure. Polishing these floors with limestone polishing powder can rejuvenate their surface, making them appear brand new. This method is particularly effective for restoring the elegance of historic buildings or maintaining the character of traditional British homes. Whether in hallways, kitchens, or bathrooms, polishing can significantly enhance the appearance and longevity of limestone.

Countertops made from limestone also benefit from polishing powder, as they often encounter spills and scratches. Regular application of polishing powder can keep these surfaces looking immaculate, ensuring they remain a focal point in your kitchen or bathroom. Additionally, polished limestone countertops are easier to clean, preventing dirt from settling into the stone’s pores, which can lead to staining over time.

Other decorative limestone elements, such as sculptures or architectural features, can also benefit from polishing. These pieces often require diligent maintenance to ensure they remain visually appealing. By using limestone polishing powder, you can restore the intricate details of these features, ensuring they continue to stand as a testament to beauty and craftsmanship.

In summary, the applications of limestone polishing powder are extensive, addressing a wide range of surfaces that require a polished finish. Understanding how and where to apply this powder can significantly enhance the appearance and durability of limestone in both residential and commercial contexts.

Common Applications in Residential and Commercial Settings

The versatility of limestone polishing powder extends to numerous applications in both home and commercial environments. In residential spaces, it has become a popular choice for restoring and maintaining limestone surfaces, particularly in high-traffic areas like kitchens and bathrooms. Homeowners frequently struggle with stains and scratches that accumulate over time. By utilising polishing powder, they can easily rejuvenate their surfaces, restoring the natural beauty and shine characteristic of limestone.

In commercial settings, the demand for immaculate surfaces is even more pronounced. Hotels, restaurants, and retail spaces often utilise limestone for its elegance and aesthetic appeal. Maintaining these surfaces is crucial for creating a welcoming environment for customers. Limestone polishing powder is routinely employed in these establishments to keep floors and countertops looking pristine. Regular polishing not only enhances visual appeal but also prolongs the lifespan of these surfaces, making it a valuable investment for businesses.

Another common application for limestone polishing powder is in the care of decorative items, such as sculptures or architectural elements found in both residential and public spaces. These elements can be particularly susceptible to wear from environmental factors and human interaction. Regularly polishing them with limestone powder ensures they continue to showcase quality craftsmanship and beauty.

In the DIY realm, homeowners increasingly opt to undertake polishing tasks independently. The simplicity of using limestone polishing powder attracts those eager to save on professional services while achieving professional results. With a bit of knowledge and the right tools, anyone can restore the beauty of their limestone surfaces, making it an empowering project that individuals can tackle with confidence.

Thus, the widespread use of limestone polishing powder across diverse environments underscores its effectiveness and versatility. Whether in a bustling commercial establishment or a serene home, polishing powder emerges as an invaluable resource for enhancing and protecting limestone surfaces.

Recognising Limitations and Taking Necessary Precautions

While the advantages of limestone polishing powder are numerous, it is equally important to recognise its limitations and the necessary precautions for safe use. This polishing powder is specifically formulated for limestone and should not be applied to other stone types or surfaces, as this may lead to unintended damage. For instance, applying limestone polishing powder on marble or granite could result in scratches or dulling of those surfaces, making it crucial to identify the material prior to application.

Moreover, the application of limestone polishing powder can generate dust, posing health risks if inhaled. As such, wearing protective gear, including a mask, gloves, and goggles, is essential to safeguard against respiratory issues and skin irritation. Ensuring proper ventilation while working with the powder can further mitigate health risks, creating a safer environment for both professionals and DIY users.

Another limitation is the requirement for a certain skill level and technique to achieve optimal results. While polishing limestone can be a straightforward task, improper methods can lead to uneven finishes or subpar outcomes. It is vital to adhere to the correct application techniques, including the appropriate amount of pressure and machine speed, to ensure an even polish.

Lastly, understanding that limestone polishing powder is not a one-time fix is essential. Regular maintenance is necessary to keep surfaces looking their best after polishing. Over time, even polished limestone can gather dirt and scratches, necessitating periodic reapplication of the powder to sustain its sheen and durability.

In summary, whilst limestone polishing powder offers remarkable benefits, it comes with limitations and necessary precautions. By understanding these factors, users can make informed decisions and apply the powder effectively, preserving the beauty and integrity of their limestone surfaces for years to come.

Comprehensive Guide to Effectively Using Limestone Polishing Powder

Successfully utilising limestone polishing powder involves a systematic approach that ensures optimal results. Preparation is key, starting with a thorough cleaning of the limestone surface. Before applying the polishing powder, ensure you remove any dirt, dust, or debris that could interfere with the polishing process. This step is critical, as any particles left on the surface can scratch the stone during polishing, negating the benefits of the process.

Once the surface is clean, you can begin the application of limestone polishing powder. An even application is crucial for achieving a uniform finish. You may either sprinkle the powder directly onto the surface or mix it with water, depending on the manufacturer’s instructions and the specific requirements of the job. Following this, utilise a polishing machine or a hand pad to buff the powder into the stone. The pressure applied during this phase can vary; for heavily scratched areas, a bit more pressure may be necessary, but always exercise caution to avoid damaging the limestone.

After achieving the desired shine, it is crucial to conclude the process correctly. Clean the surface again to remove any residue from the polishing powder. This step ensures that no dust or particles remain that could detract from the polished appearance. To maintain the results over time, establish a regular maintenance routine that includes cleaning and periodic reapplication of the polishing powder as needed.

Safety precautions cannot be overlooked throughout this entire process. Always wear protective gear, including gloves and goggles, to shield yourself from any dust particles or chemicals that could be harmful. Ensure you work in a well-ventilated area, reducing the risk of inhalation and ensuring a more comfortable working atmosphere.

In essence, mastering the use of limestone polishing powder involves preparation, application, finishing, and safety measures. By meticulously following these steps, you can achieve stunning results that restore and enhance the beauty of your limestone surfaces.

Thoroughly Prepare the Surface for Optimal Polishing Outcomes

Preparing the surface before applying limestone polishing powder is a vital step that lays the groundwork for a successful polishing process. The first action is to clean the limestone thoroughly. This entails removing any dirt, dust, grease, and grime that may have accumulated over time. A simple solution of warm, soapy water can be effective; however, ensure that no harsh chemicals are used, as these can damage the surface of the limestone.

When cleaning, consider employing a soft brush or cloth to scrub the surface gently. Avoid anything abrasive that might scratch the stone. Once cleaned, rinse the area thoroughly with clean water to eliminate any soapy residue, as this could impact the polishing process. It’s crucial to allow the surface to dry completely before proceeding to the next step, as moisture can interfere with the adhesion and effectiveness of the polishing powder.

Conducting a thorough assessment of the limestone surface is also beneficial during the preparation stage. Identify any significant scratches, stains, or areas of wear that may require extra attention during polishing. By understanding the condition of the surface, you can adjust your approach, applying more pressure or spending additional time on problematic areas during the polishing process.

In summary, preparing the limestone surface is critical for maximising the effectiveness of limestone polishing powder. A clean, dry, and well-assessed surface ensures that the polishing adheres correctly and delivers the best possible results.

Master Effective Application Techniques for Polishing

Mastering the application techniques for limestone polishing powder can significantly enhance the outcome of your polishing project. Once you have prepared the surface, the next step is to apply the polishing powder effectively. There are two primary methods to use: dry application and wet application. Your choice will depend on the specific product instructions and the condition of the limestone.

For the dry application, sprinkle an even layer of polishing powder over the surface. It’s essential to apply the powder uniformly to avoid any uneven polishing. This technique works well for lightly scratched surfaces, allowing the powder to work its magic as it is buffed in. Using a polishing machine will yield the best results, as it enables consistent pressure and speed, which are both crucial for achieving a smooth finish.

Wet application, on the other hand, involves mixing the polishing powder with a small amount of water to create a paste. This technique is beneficial for surfaces with more significant scratches or stains, as the paste can penetrate more effectively and facilitate deeper cleaning. When using this method, apply the paste with a soft cloth or polishing pad, working it into the stone using a circular motion.

Regardless of the chosen method, it is vital to apply consistent pressure while buffing the surface. This ensures that the powder performs its function of smoothing out scratches and restoring the shine effectively. For larger areas, using a polishing machine can save time and provide a uniform finish. However, for smaller sections or delicate surfaces, hand polishing may be more appropriate.

As you polish, take breaks to assess your progress, ensuring an even shine across the entire surface. Once you have achieved the desired level of polish, it is essential to clean the surface again to remove any remaining powder residue.

In conclusion, the application techniques for limestone polishing powder are straightforward yet pivotal in achieving stunning results. Whether opting for dry or wet application, the key lies in even distribution, consistent pressure, and regular assessment throughout the process.

Add the Finishing Touches and Establish Ongoing Maintenance

Once you have polished your limestone surface with limestone polishing powder, taking the time to finish properly can significantly enhance the longevity of your results. After buffing the surface to a stunning shine, it is essential to clean away any residual polishing powder. This is best accomplished with a damp cloth or sponge, ensuring that all traces of the powder are eliminated. Allow the surface to dry thoroughly before using it or applying any sealants.

Beyond immediate cleaning, establishing a routine maintenance schedule is crucial for preserving the polished appearance of your limestone surfaces. Regular cleaning with non-abrasive products will help maintain the stone’s beauty. It is advisable to utilise a pH-neutral cleaner specifically designed for stone surfaces to avoid damage. Additionally, consider implementing a weekly or monthly routine to check for any signs of wear and to reapply polishing powder as necessary.

Maintaining the shine on your limestone surfaces involves more than just cleaning; it also requires protecting them from potential stains and scratches. You can apply a high-quality stone sealer after polishing to create an additional barrier against spills and dirt. This sealing process enhances the longevity of your polished finish, allowing you to enjoy your beautifully restored limestone for years without worry.

In summary, the finishing touches and maintenance of surfaces treated with limestone polishing powder are integral to ensuring their beauty and functionality. Regular upkeep and protective measures will not only preserve the investment in polishing but also enhance the charm and elegance of your limestone surfaces.

Essential Safety Precautions When Handling Polishing Powder

When working with limestone polishing powder, prioritising safety is paramount. This powder can produce dust when applied, which poses potential health risks if inhaled. Therefore, wearing a suitable mask or respirator is crucial, helping protect against respiratory issues that may arise from prolonged exposure to airborne particles generated during the polishing process.

Protective gloves and goggles are equally important. Gloves will shield your hands from irritation caused by the powder, while goggles will protect your eyes from dust and potential splashes of any cleaning solution you may use in conjunction with the polishing powder. These simple yet effective safety measures significantly reduce the risk of injury or discomfort during the polishing process.

It is also advisable to work in a well-ventilated area. Proper airflow can help disperse any dust or fumes, ensuring a safer environment as you polish your limestone surfaces. If you are working indoors, consider using fans or opening windows to enhance ventilation.

Another vital point to consider is to follow the manufacturer’s instructions explicitly. Each product may come with specific guidelines regarding safety and application techniques. Ignoring these guidelines can lead to unintended consequences, including damage to surfaces or health risks.

In summary, taking safety precautions when using limestone polishing powder is not just a courtesy; it is a necessary step in ensuring a successful and safe polishing experience. By equipping yourself with the right protective gear and adhering to safety guidelines, you can provide a smooth and worry-free process.

Guidelines for Selecting the Most Suitable Limestone Polishing Powder

Choosing the ideal limestone polishing powder is crucial for achieving the best possible results. Not all powders are created equal, and selecting the right one tailored to your specific needs can dramatically affect the outcome of your polishing efforts. The first step in this process is understanding the types of limestone polishing powders available in the market.

Generally, polishing powders come in two primary types: powdered form and liquid form. Powdered polishing agents tend to be more commonly used due to their effectiveness in providing a high shine. However, some liquid formulations are also available, often combined with other cleaning agents, which can offer additional benefits such as stain removal. Selecting the type that best suits your requirements will be your first significant decision.

Moreover, consider the specific types of limestone you are working with. Different varieties of limestone can have varying hardness and texture, which may require different polishing powders. For instance, softer limestones may benefit from finer powders, while harder varieties might need a more abrasive product to achieve the desired results. Always check the product specifications to ensure compatibility with your limestone type.

Another key consideration when choosing limestone polishing powder is the level of wear on the surface you are working with. If the limestone is heavily scratched or stained, you will likely need a more aggressive polishing powder to restore its original beauty. Conversely, if the surface is merely dull, a lighter polishing powder may suffice for a touch-up. Assessing the condition of your limestone will guide you in selecting the right product.

Finally, purchasing limestone polishing powder from reputable suppliers is crucial. Look for brands that have established themselves in the industry and come with positive customer reviews. Local hardware stores, home improvement centres, and various online retailers are great places to explore options. Always read product labels and descriptions carefully, taking note of any additional features or benefits that may enhance your polishing experience.

In conclusion, choosing the right limestone polishing powder involves understanding the types available, considering the specific limestone type, assessing the wear level, and purchasing from trusted suppliers. Making informed choices in these areas will lead to successful polishing results and maintain the beauty of your limestone surfaces.

Exploring the Variety of Limestone Polishing Powders Available

When it comes to limestone polishing powder, understanding the various types available is key to practical use. As previously mentioned, there are generally two primary forms: dry powders and liquid formulations. Each type has its unique advantages and is suitable for different applications.

Dry polishing powders are typically composed of finely ground limestone and other minerals, designed explicitly for polishing stone surfaces. They are widely favoured because of their effectiveness in restoring shine and clarity. These powders can be applied directly to the surface or mixed with water for a paste-like consistency, depending on the specific requirements of the job. The versatility of dry powders makes them suitable for both light touch-ups and more rigorous restoration tasks.

On the other hand, liquid polishing products often contain a blend of polishing agents and cleaning compounds. These formulations can provide additional benefits, such as stain removal and cleaning, making them ideal for surfaces that require both polishing and deep cleaning. Liquid powders may be easier to apply and often require less manual effort, appealing to those who prefer a quicker, less labour-intensive method of surface restoration.

Additionally, some products may be formulated specifically for different types of limestone. For instance, certain polishing powders are tailored to softer varieties of limestone, while others may be designed for denser stones. Selecting the right product for your limestone type ensures that you achieve the best possible results without compromising the integrity of the stone.

Ultimately, the choice between dry and liquid polishing powders, as well as understanding the specific formulations for different types of limestone, will enhance your ability to care for and maintain your limestone surfaces effectively. Knowing these distinctions helps ensure that you select the right limestone polishing powder for your unique polishing needs.

Key Factors to Consider When Buying Limestone Polishing Powder

When looking to purchase limestone polishing powder, several essential factors should guide your decision-making process. First and foremost, consider the type of limestone you possess. Different varieties can exhibit unique characteristics, and certain polishing powders may be better suited to specific kinds of limestone. For example, softer limestones might require gentler polishing agents, whereas harder varieties can handle more abrasive options.

Another critical factor is the level of wear and tear on the limestone surface you intend to polish. If the stone has significant scratches or stains, you will need a more aggressive powder to achieve the desired results. Conversely, if the surface is relatively intact and just in need of a refresh, a lighter polishing powder may be more appropriate. Assessing the condition of your limestone will help you select a powder that matches its needs.

Additionally, consider the manufacturer’s recommendations and product specifications. Different brands might offer unique formulations designed for various applications, and following these guidelines can significantly affect the polishing outcomes. Look for products that provide clear usage instructions and compatibility information, ensuring you use the correct powder for your specific job.

Price is also a factor, but it should not be the sole deciding element. While you may find cheaper options, investing in a reputable brand often leads to better results and greater satisfaction. When it comes to polishing limestone surfaces, quality can make a significant difference in the outcome, so it can be worth spending a little more for a product that delivers superior results.

In conclusion, when buying limestone polishing powder, it is essential to consider the limestone type, the level of surface wear, manufacturer recommendations, and the balance between cost and quality. Making informed choices based on these factors will lead to successful polishing results and long-lasting beauty for your limestone surfaces.

Where to Source High-Quality Limestone Polishing Powder

Finding the right place to purchase limestone polishing powder can significantly influence your overall experience and results. Limestone polishing powder is available through various channels, including local hardware stores and home improvement centres. Visiting these establishments allows you to consult with knowledgeable staff, who can provide insights and recommendations based on your specific needs. They can guide you toward the best products available, ensuring you leave with the right polishing powder for your project.

Online shopping has also become a popular option for sourcing polishing powder, offering the convenience of browsing multiple brands and products from the comfort of your home. Websites dedicated to home improvement, stone care, and cleaning supplies often feature a wide selection of limestone polishing powders. When opting for online purchases, take the time to read customer reviews and product ratings to gauge the effectiveness and reliability of the products you’re considering.

Specialty suppliers that focus on stone care products are another excellent resource. These retailers often carry professional-grade polishing powders, which may not be readily available in traditional retail outlets. Shopping with specialty suppliers can also provide access to expert advice and guidance on the best products for your specific limestone type and condition.

When purchasing limestone polishing powder, be sure to check for compatibility with your specific type of limestone, the desired finish, and any additional features that may enhance your polishing experience. By exploring various purchasing avenues and seeking out quality products, you can ensure that your limestone surfaces receive the care they deserve.

Health and Environmental Considerations for Using Limestone Polishing Powder

When working with limestone polishing powder, prioritising safety and environmental considerations is paramount. The inhalation of dust generated during the polishing process can pose health risks, particularly for those with respiratory sensitivities. Consequently, it’s essential to wear protective gear, including masks or respirators, to minimise the risk of inhaling harmful particles. Additionally, working in well-ventilated areas helps disperse dust and keeps the work environment safer.

Another critical aspect of safety is the handling and disposal of used polishing powder. The powder should never be disposed of in regular waste; instead, adhere to local regulations regarding hazardous materials. Many areas have specific guidelines for disposing of construction or cleaning materials, so be sure to follow these to prevent environmental contamination.

As the call for eco-friendly practices grows, considering environmentally safe alternatives for polishing limestone surfaces becomes increasingly essential. Some brands now offer eco-friendly limestone polishing products that utilise biodegradable ingredients and natural abrasives. These options provide a safer choice for both users and the environment, ensuring that your polishing efforts do not come at the expense of ecological health.

In the workplace, providing training on safe handling procedures for limestone polishing powder is also essential. Workers should be aware of the proper techniques for using the powder, the importance of wearing protective equipment, and the protocols for dealing with emergencies. By fostering a culture of safety and awareness, you can significantly reduce the risk of accidents and injuries associated with the use of limestone polishing powder.

In summary, understanding the safety and environmental considerations linked to limestone polishing powder is essential for ensuring a successful polishing experience. By prioritising protective measures, responsible disposal, and considering eco-friendly alternatives, users can enjoy the benefits of polishing while safeguarding both their health and the environment.

Identifying Health Risks Associated with Limestone Polishing Powder

When using limestone polishing powder, awareness of potential health risks is crucial. One of the primary concerns is the inhalation of dust particles generated during application. Breathing in these particles can lead to respiratory issues, particularly for individuals with pre-existing conditions such as asthma or other lung diseases.

To mitigate these risks, it is essential to use personal protective equipment (PPE), including masks or respirators that are specifically designed to filter out fine dust particles. This precaution will help safeguard your respiratory health while working with polishing powders. Additionally, ensuring that the work area is well-ventilated can further reduce the concentration of airborne particles and promote a safer working environment.

Skin irritation is another potential issue when handling limestone polishing powder. The powder can cause dry skin or irritation upon direct contact, which is why wearing gloves during application is highly recommended. This simple measure provides a barrier between the skin and the powder, minimising the risk of irritation or allergic reactions.

Eye protection is equally important, as dust particles can become airborne during the polishing process. Wearing safety goggles can protect the eyes from dust and any splashes from cleaning solutions used in conjunction with the polishing powder.

In conclusion, understanding the health risks associated with limestone polishing powder can empower users to take appropriate safety measures. By prioritising protective equipment and ensuring proper ventilation, you can significantly reduce health risks while enjoying the benefits of polished limestone surfaces.

Proper Disposal of Used Polishing Powder

Proper disposal of used limestone polishing powder is essential to prevent environmental contamination and adhere to local regulations. The powder, often considered a construction or cleaning waste product, should not be disposed of with regular household waste. Instead, it is crucial to research local disposal guidelines, as many areas have specific regulations governing the disposal of polishing powders and similar materials.

One option is to check with local waste management facilities to see if they accept construction and cleaning waste. Some facilities have designated drop-off locations for such materials, ensuring they are handled and disposed of safely. Always ensure you are following the guidelines provided by your local authorities to avoid potential penalties or fines.

In addition to following local regulations, consider exploring eco-friendly disposal options. Some communities offer recycling programs or special collection days for hazardous materials, providing an opportunity to dispose of used polishing powder responsibly.

If you are uncertain about the disposal process, seeking guidance from the manufacturer of the polishing powder can be beneficial. Manufacturers often have recommendations or resources related to safe disposal practices, helping you navigate the process effectively.

In summary, ensuring the safe disposal of limestone polishing powder involves adhering to local regulations, exploring eco-friendly options, and seeking guidance from manufacturers. By taking these steps, you can protect the environment while responsibly managing your polishing waste.

Eco-Friendly Alternatives to Traditional Limestone Polishing Powder

In today’s environmentally conscious world, the demand for eco-friendly alternatives to traditional materials is rising, and limestone polishing powder is no exception. Several eco-friendly polishing products have emerged, designed to minimise environmental impact while still delivering effective results. These alternatives often utilise biodegradable ingredients that are friendlier to both users and the planet.

One such option includes polishing powders made from natural minerals and organic compounds. These products effectively clean and polish limestone surfaces without introducing harmful chemicals into the environment. By opting for these eco-friendly products, users can achieve beautiful, polished limestone while reducing their ecological footprint.

Another avenue to explore is the use of homemade polishing solutions. For those who prefer a DIY approach, a simple mixture of baking soda and water can serve as a gentle abrasive for polishing limestone. This natural alternative can effectively remove minor scratches and restore shine without the risks associated with commercial polishing powders.

Moreover, many eco-friendly brands prioritise sustainable sourcing and packaging, ensuring that their products are not only practical but also responsible. When searching for limestone polishing products, look for certifications or eco-labels that indicate a commitment to sustainability and environmental stewardship.

In conclusion, the availability of eco-friendly alternatives to limestone polishing powder offers users the opportunity to maintain their limestone surfaces while prioritising environmental health. By choosing sustainable products or exploring DIY solutions, you can preserve the beauty of your limestone without compromising the planet.

Highlighting the Importance of Protective Equipment and Training for Safe Use

The use of limestone polishing powder necessitates the proper protective equipment and training to ensure a safe working environment. As previously discussed, protective gear, including masks, gloves, and goggles, is essential to safeguard against dust inhalation, skin irritation, and eye exposure. Ensuring that all personnel involved in limestone polishing are equipped with the appropriate PPE significantly reduces the risk of accidents and health issues.

Training is equally vital for those who will be using polishing powder. Workers should be educated on safe handling practices, including the proper techniques for applying the powder and maintaining a clean work environment. This includes understanding the importance of wearing protective equipment, ensuring adequate ventilation, and following safe disposal methods for used polishing powder.

Regular training sessions can reinforce the importance of safety protocols and ensure that everyone is up to date with the latest best practices in using limestone polishing products. Encouraging a culture of safety and awareness will not only help protect individuals but also improve the overall quality of work performed.

In summary, investing in proper protective equipment and training is essential when working with limestone polishing powder. By prioritising safety measures and educating users on best practices, you can create a safe and effective environment for polishing limestone surfaces.

Troubleshooting Common Issues with Limestone Polishing Powder

Even with the best preparation and techniques, issues can arise when using limestone polishing powder. Being able to troubleshoot these common problems can save time and effort while helping you achieve the best results possible.

One common issue is uneven polishing, where some areas of the limestone surface appear shiny while others remain dull. This can often occur when the application of polishing powder is inconsistent. To address this, reapply the polishing powder to the affected areas and use a polishing machine or hand pad to buff it evenly. Taking your time and ensuring consistent pressure across the entire surface is key to achieving a uniform finish.

Another problem might be the persistence of stains or scratches even after polishing. If this occurs, it could indicate that the polishing powder used is not suitable for the level of wear on the limestone surface. In such cases, switching to a more aggressive polishing powder or a product specifically designed for stain removal may be necessary.

If the limestone appears cloudy post-polishing, this could be due to residue left from the polishing powder. This issue can be resolved by cleaning the surface again with a damp cloth to remove any remaining particles. Ensure you rinse thoroughly to avoid leaving behind any cleaning agents that could affect the finish.

In summary, troubleshooting common issues with limestone polishing powder involves being proactive and attentive during the polishing process. By recognising potential problems and addressing them promptly, you can ensure the successful restoration and maintenance of your limestone surfaces.

Resolving Challenges with Uneven Polishing

Encountering uneven polishing when using limestone polishing powder can be frustrating, but it is a common issue that can be resolved effectively. Uneven polishing typically manifests as patches of shine interspersed with dull areas, often resulting from inconsistent application or insufficient buffing in certain spots.

To rectify this issue, the first step is to identify the areas that require additional attention. Once you’ve pinpointed these spots, reapply the polishing powder directly to the uneven areas. It’s essential to use a generous amount to ensure effective treatment. Following this, it’s vital to buff the area thoroughly with a polishing machine or a hand pad. Pay close attention to the pressure applied; consistent pressure across the surface will help achieve a more uniform finish.

If the unevenness persists despite reapplication, consider adjusting your techniques. For instance, if you are using a polishing machine, double-check the speed settings and ensure that you are moving the machine in a consistent pattern. Slower, more deliberate movements can often yield better results, especially in larger areas.

In conclusion, dealing with uneven polishing involves a combination of reapplication, careful buffing, and technique refinement. By approaching the problem methodically and making necessary adjustments, you can restore the beauty and shine of your limestone surfaces effectively.

Effectively Tackling Stains on Limestone Surfaces

Stains on limestone surfaces can be remarkably stubborn, and addressing them effectively while using limestone polishing powder requires a thoughtful approach. The first step is to identify the type of stain present, as different stains require different treatment methods. Common culprits include oil, wine, and food stains, which can penetrate the porous surface of limestone.

For oil-based stains, a poultice made from the polishing powder mixed with water can be especially effective. Apply the paste to the stained area and cover it with plastic wrap, allowing it to sit for an extended period. The powder will draw out the oil from the limestone, assisting in reducing or eliminating the stain.

For food or wine stains, it is often best to use a gentle cleaning solution, such as a mixture of warm water and a pH-neutral soap. Avoid acidic cleaners, as they can damage limestone. Apply the solution with a soft cloth and rinse thoroughly with clean water. Once the stain is addressed, follow up with polishing powder to restore the shine.

Another option is to use a commercial stain remover designed specifically for limestone. These products can be particularly valuable for stubborn or set-in stains, as they contain formulations tailored for stone care. Always follow the manufacturer’s instructions for best results.

In summary, addressing stains on limestone surfaces requires careful consideration and targeted approaches. By understanding the type of stain and using the appropriate cleaning or poultice methods, you can effectively treat stains while still benefiting from the use of limestone polishing powder for polishing and restoration.

Frequently Asked Questions About Limestone Polishing Powder

What are the key ingredients in limestone polishing powder?

Limestone polishing powder primarily consists of finely ground limestone particles, often combined with other minerals to enhance its polishing properties and effectiveness.

What is the mechanism of action for limestone polishing powder?

It functions by gently abrading the surface of limestone, smoothing out scratches and restoring the natural shine, making the stone appear revitalised and attractive.

Can limestone polishing powder be applied to other types of stone?

No, limestone polishing powder is formulated explicitly for limestone surfaces. Using it on other stone types may cause damage and undesirable results.

Is limestone polishing powder safe to use?

When utilised correctly with appropriate safety precautions, such as wearing a mask and protective gear, limestone polishing powder is safe for polishing and restoring limestone surfaces.

How often should I consider polishing my limestone surfaces?

The frequency of polishing depends on usage and wear; typically, polishing every 6 to 12 months is adequate for maintaining the shine and appearance of limestone surfaces.

Can I perform limestone polishing as a DIY project?

Yes, polishing limestone can be undertaken as a DIY project. With the right tools, techniques, and polishing powder, homeowners can achieve professional-looking results.

What benefits does polishing limestone provide?

Polishing limestone enhances its appearance by restoring shine, improves its durability, and makes the surface more resistant to stains and damage.

Are there eco-friendly alternatives to limestone polishing powder?

Yes, eco-friendly polishing powders made from natural ingredients or DIY solutions like baking soda can serve as effective alternatives for polishing limestone surfaces.

What are the safe disposal methods for used polishing powder?

Used polishing powder should be disposed of in accordance with local regulations for hazardous materials. Check with local waste management facilities for safe disposal options.

What steps should I follow if my limestone surface appears uneven after polishing?

If you encounter uneven polishing, reapply the powder to the affected areas and buff them thoroughly until you achieve a uniform finish across the entire surface.

The Article What is Limestone Polishing Powder: A Comprehensive Guide first found on https://london-stone.co.uk

The Article Limestone Polishing Powder: Your Essential Guide Explained appeared first on https://fabritec.org

The Article Limestone Polishing Powder: A Comprehensive Guide Was Found On https://limitsofstrategy.com